Tech Pack Mastery. Breaking Down the Most Important Document in Apparel Design.

What goes into a tech pack and why is it so crucial in apparel design?

The tech pack is universally recognised as the gold standard when it comes to product design. This article aims to share the process a brand goes through to building a well rounded tech pack, and the elements that go into it.

We’ll explore the role of the tech pack in facilitating sampling, who’s involved, and how to communicate clearly with the factory.

What is a tech pack?

First of all, let’s break down what a tech pack is. A tech pack is a document which translates all the necessary information needed for a factory to develop a product. It is, in theory, the blueprint.

Whilst all tech packs vary in terms of their contents, most include information such as measurements, fabric, trims and components alongside CAD drawings of the product.

The clearer the tech pack is, and the clearer the information is laid out, the greater chance of achieving a better sample. Its important to note that the tech pack is a working document, forever changing.

In most cases, it is the product developer that owns the tech pack, ensuring all information is up to date. This document is the go-between for the brand and the factory, so in order for samples to be correct to your specification, its imperative that the information on the tech pack is complete.

The CAD

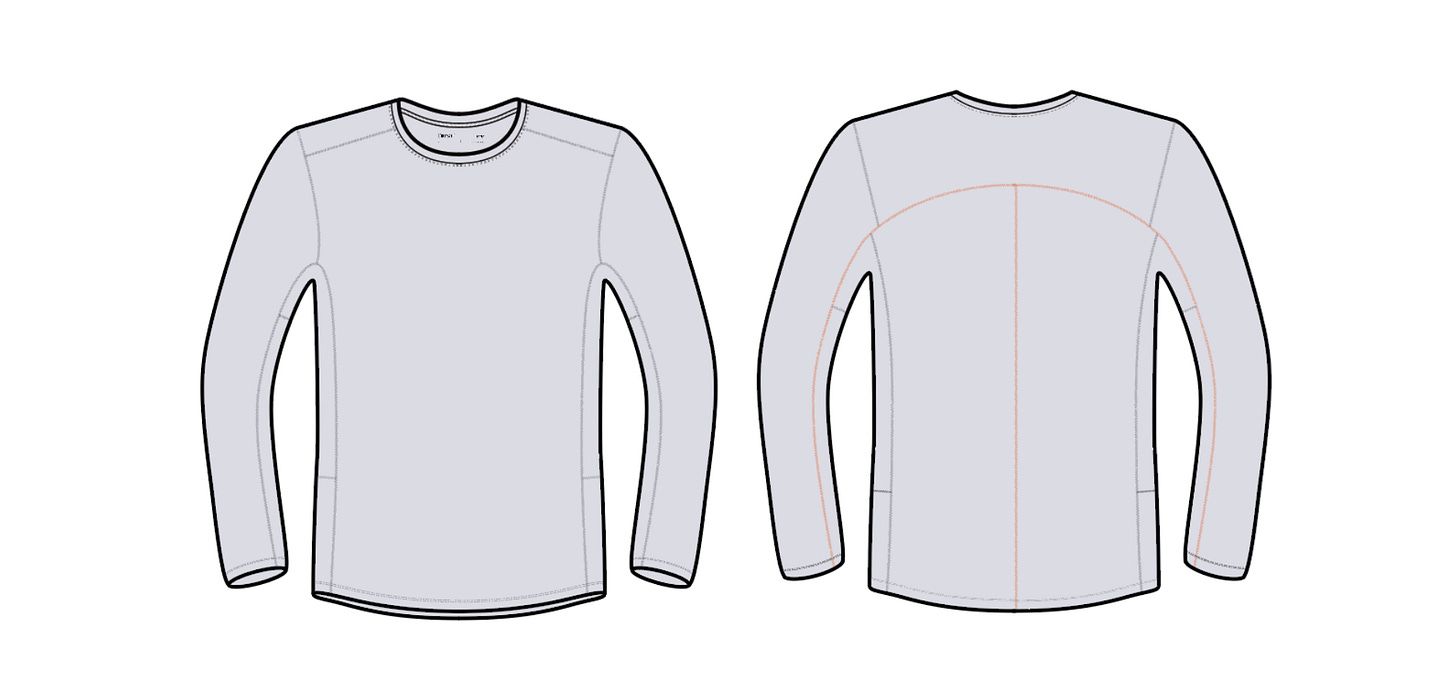

The CAD is a visual representation of the product and usually consists of a sketch done in Adobe Illustrator (or similar software).

The CAD is a simplified version of the sketches or detailed drawings that your designer, or design team has done at the previous stage of the design process. An example below shows developed drawings Torsa had for their SS25 Merino T-Shirt styles.

These, are of course, a more stylised version of a CAD. The next step would be to translate these into a simplified version for the factory to reference.

Above shows the final CAD drawing which was included in our tech pack for our SS25 Merino LS. Although it appears simple, in the case of our Merino LS above, it would illustrate style lines, back neck binding, neck seam stitching + stitching elsewhere, and label placement. This is the main source of visual product representation for the factory to follow, so it needs to have the correct details.

The Measurement Spec

Imperative on all tech packs, the measurement spec (or point of measure) is the detailed break down of measurements for the garment.

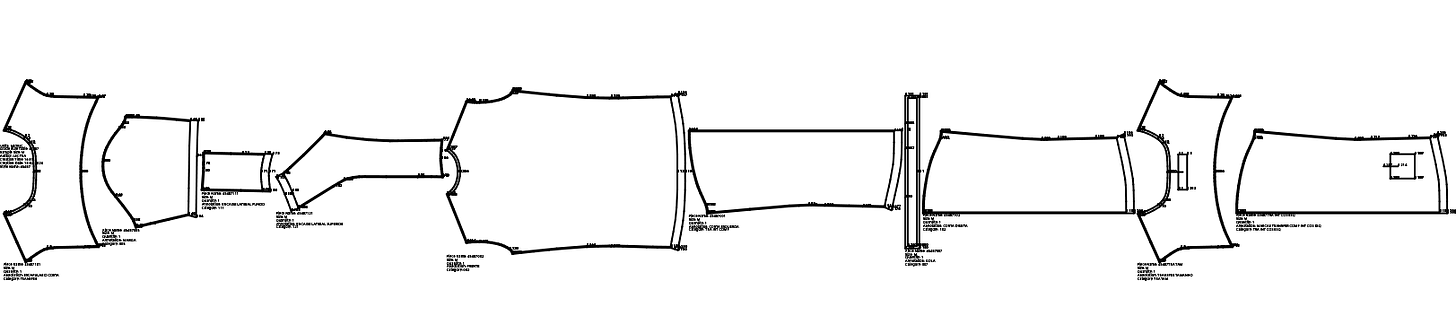

Measurements are needed to create pattern files. Patterns are essentially the different components or pieces that make up the product. These are created either by your in-house pattern maker, or in the case of many start ups where resources are limited, the factories pattern maker. An example of what a pattern looks like can be reviewed below.

Whilst patterns are rarely included in a tech pack (instead alongside it in DXF file format) it’s important to mention how the pattern is made.

The role of the pattern maker is to use their knowledge and experience to translate the measurement spec into a pattern for the factory to cut. Fit is obviously a crucial element of product design, and from experience, I can’t stress the importance of firstly getting the right measurements, but secondly, finding a super talented pattern maker to develop your patterns.

An example of a measurement spec can be seen below;

As you can see, even in the case of a long sleeve t-shirt, the number of measurements is pretty extensive. In the case of Torsa, our product developer was responsible for ensuring all measurements were taken and updated on the tech pack.

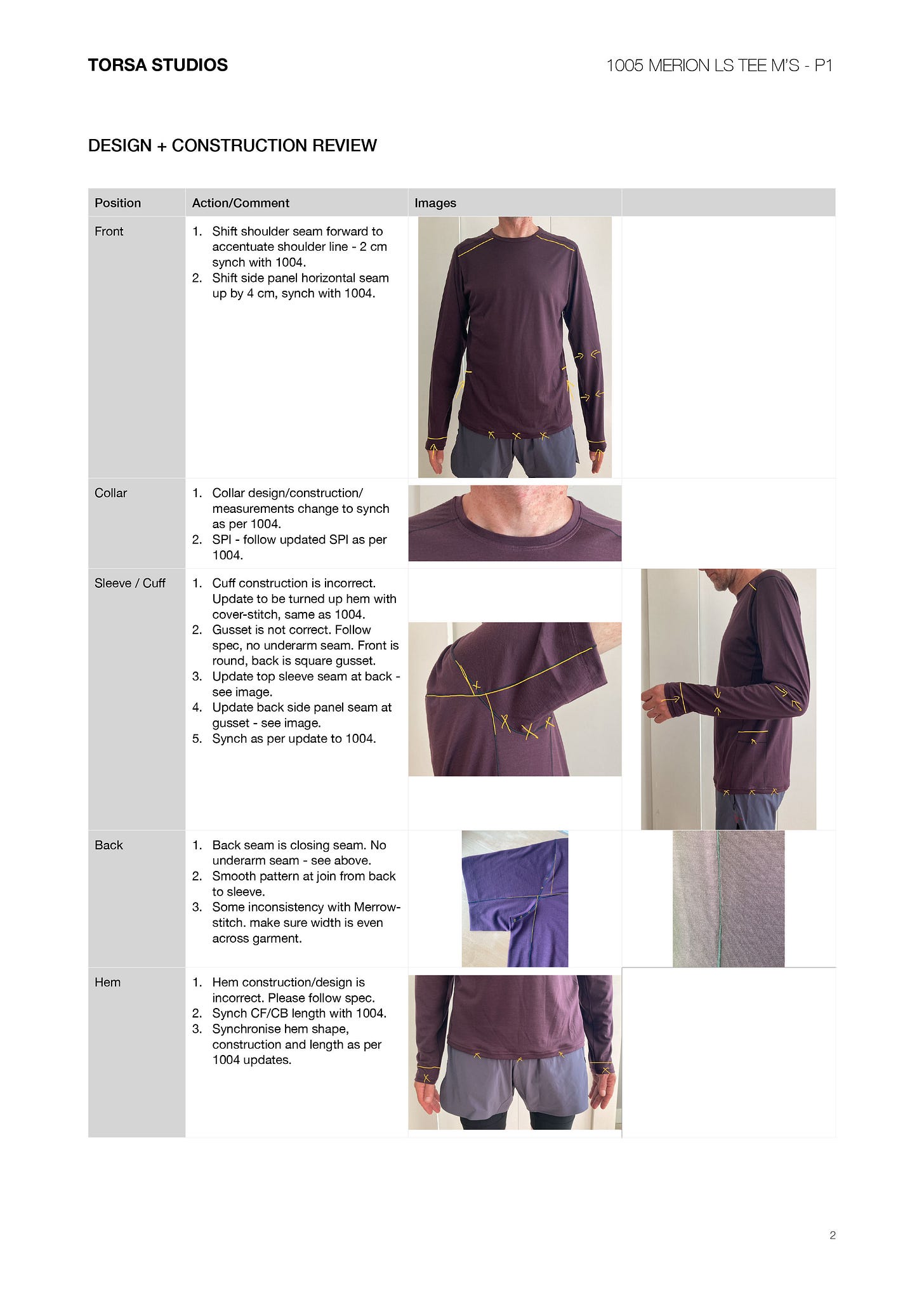

Changes to measurement spec and details would come on the back of a design and construction review. At this stage, your design team comes together to asses the first samples. This stage is critical but I will cover the sampling process in more depth in a future article.

Fabric and Trim Spec

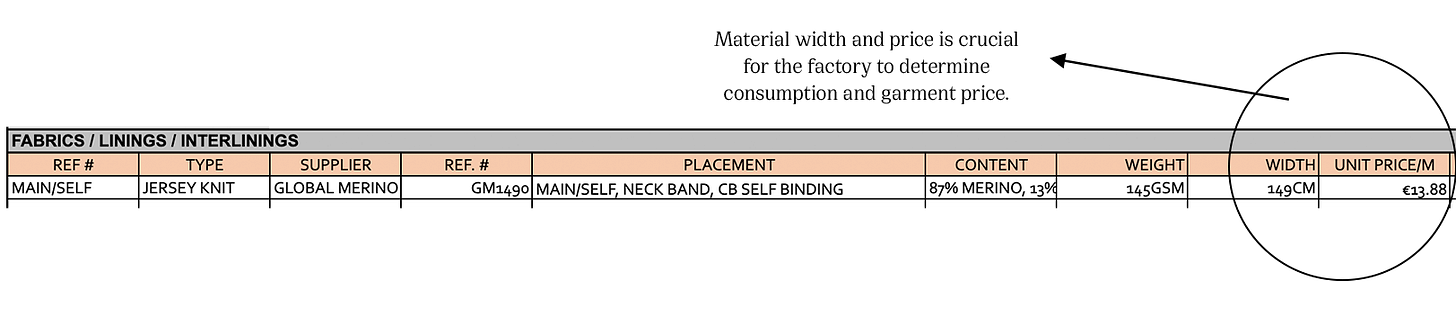

The fabric, trims and components spec consist of all the necessary information related to materials needed to construct the garment. Remember, each garment you create is usually made up of multiple fabrics and trims, and therefore having rows on your tech pack which differentiate your materials / trims is critical. It’s best to split up this part of the tech pack into specific components. In our case, we do this by category as follows;

Fabrics / linings / interlinings

Trims

Garment labels / logos

Zippers

Packaging / swing tags

Although something like a long sleeve t-shirt may consist of one fabric, consider a technical outerwear jacket for example. This may use multiple fabrics; shell fabric, liner fabric, pocket interlining, and so on. It’s crucial to not only list these on the tech pack, but also specify the placement of each fabric.

When it comes to material, it’s also crucial to list the fabric supplier and article reference. Therefore, if the factory is ordering on your behalf, they are fully aware of which fabric they have to order for sampling and production.

Not only this, the price per metre and fabric width is also essential. Remember fabrics will arrive in rolls, at a certain width. This can range by supplier and article. This is crucial because the factory has to cut the patterns (made by the pattern maker) out of these rolls. Each garment will have a different consumption or usage. Whilst a sleeveless running jacket may have a consumption of 1 metre, a longsleeve training jacket with hood might be 2.2 metres.

So, if you’re using the same fabric for the sleeveless jacket and long sleeve jacket, the total fabric cost for each garment will be very different.

Sleeveless jacket - 1 metre x $10 = $10 per garment

Training jacket - 2.2 metres x $10 = $22 per garment

This is why width can be an important aspect to look at when sourcing your fabrics.

The fabric and trim spec, like the rest of the tech pack, must be kept up to date. This is simply critical to ensuring a successful sampling process. Even things such as a thread change may alter the garment completely, so every change discussed internally at design and development meetings must be transferred onto the tech pack.

Colour Information

Another aspect to include in your tech pack is the colour information. This not only relates to your products colour ways, (although this is important), but also the colours related to any trims, details, labelling etc.

If we take Torsa’s SS25 Run Shorts for example, CADs have been created to represent each colour way and all the corresponding information as it relates to details and trims are listed below;

As you can see, there are a number of elements that go into a colour spec. In the case of these shorts, we have to specify components such as liner, drawcord, embroidery, binding, zippers and labels.

Its again very important that these details are 100% accurate as the factory will likely be ordering these when it comes round to production. If the factory are responsible for ordering 1,000 drawcords for example, you want to be completely sure you have noted down the right Pantone colour. It’s easy to overlook small details like this, but from experience, being careless here can lead to very expensive mistakes.

Reference Images

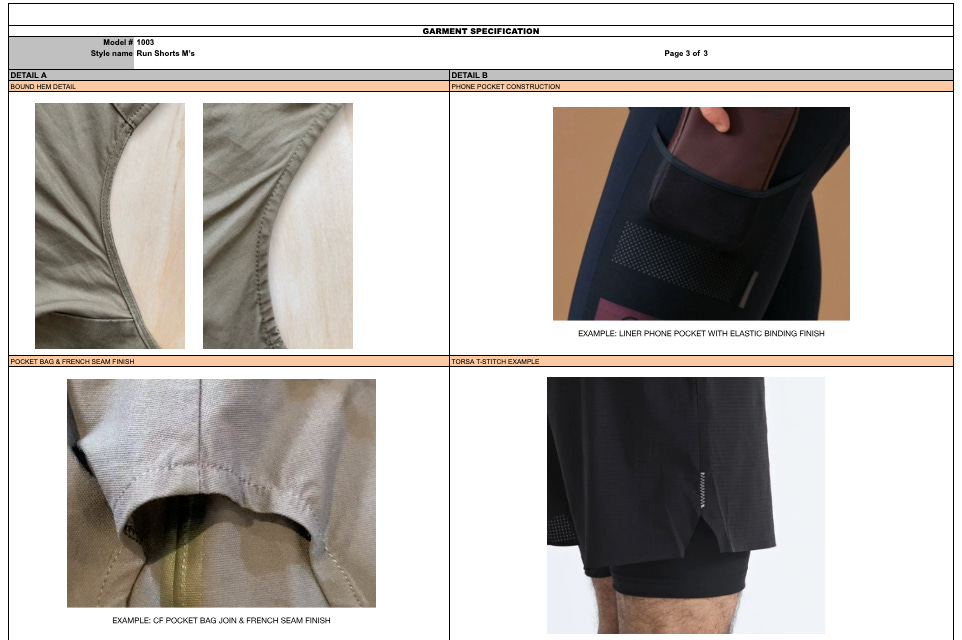

Information that is clearly articulated on the tech pack is going to help the sampling process massively. Images are one of the best tools you can use to ensure the factory understand what it is you’re referencing when it comes to a certain detail or component on the garment.

You’ve heard the saying “a picture paints 1,000 words” and in relation to tech packs, no truer words are spoken. When you’re developing a garment, it’s likely you are working with an overseas manufacturer, in which you don’t share the same mother tongue. Although you have handover calls and discussion about certain details, reinforcing this with reference imagery is always a great practice to get into.

For example, trying to articulate in words how you want the pocket bag on a pair of shorts to be finished is difficult, but once you add an image, it takes out much of the guess work.

I’d argue that reference images are one of the most important elements to a tech pack. Not only does it ensure the details are done correctly first time, it will also help limit the rounds of sampling you need to do, reducing cost and strengthening the brand-factory relationship.

Trims, Labels, Prints, Embroideries

The final section we add to our tech pack are the images in relation to trims. This will specifically include elements such as label artwork, embroideries, swing tag, drawcords, and so on.

All of these elements should be listed in the fabric and trim spec, but it is useful to provide images for the factory. For Torsa, we also included the artwork labels in terms of sizing. That way, the factory are able to contact the chosen supplier with the artwork to make sure they are ordering the correct size for samples.

Whilst this section isn’t necessarily a must-have, it’s also useful so that the factory can cross check what they receive from the chosen supplier with what is shown in the imagery. There may be some cases where mistakes are made, suppliers send the wrong item, and the only way of knowing if its incorrect is by checking it against the imagery.

This section is just another way to limit the mistakes that can occur in sampling and provides added information for your manufacturer to follow.

Final Thread

The tech pack is undoubtedly one of the most important and universally recognised documents in apparel design. A great tech pack doesn’t just have lots of information in it, but instead, has clear and concise information which the factory can understand and follow.

All tech packs will look different, so its worth speaking to your factory to determine what layout works for them. Maybe they have a template you can work from, or have snapshots of other clients they are at liberty to share.

The details that go into a tech pack are the blueprint for your garment. The better your tech pack, the better your sampling stage will be. For a start-up, this is critical. It’s always recommended that you work with designers and product developers that have had previous experience creating tech packs at other established apparel brands. That way, you know the tech packs you’re sending to manufacturers are both professional and recognisable.

Good article

This was hands down one of the clearest explanations of a tech pack I’ve seen - and that’s saying something.

Appreciate how you broke it down without getting lost in jargon or 50-slide decks.

Will definitely be coming back to this. Great work!