Unraveling Fabric Sourcing: Navigating the Financial and Logistic Challenges.

Good morning, and happy Friday. This week marked a week of change, as I moved to Portugal for the next 3 months (but probably longer). The reason for the move was twofold. Firstly, to base myself closer to our manufacturer as I oversee the development of our new run capsule collection launching next year. Secondly, it is to fulfil my second love in life - surfing. Balancing Torsa, training and surfing has something I have been trying to do for a while, and very happy to finally made it happen. I will be back and forth with London frequently, so please do reach out if you want to connect. The idea of moving goods around leads nicely into my topic this week; freight and logistics.

Topics

📉 Why fabric sourcing for start-ups suffer from ‘economies of stale’

💸 Breaking down fabric surcharges and why they have such an impact

🌍 Evaluating the decision between sourcing from Asia or Europe

🚢 The impact freight and duties have on importing

The challenges you face as a start-up are seemingly endless. This is not me bemoaning being a start-up founder, I absolutely love it and the challenges it brings, but it’s the harsh truth when you’re starting out.

A lot of these challenges, especially when it comes to manufacturing are dictated because of the size of your brand. Unless you have significant financial investment, when starting out, your orders are going to be small, right across the board. We’ve all heard of economies of scale;

Economies of scale

A proportionate saving in costs gained by an increased level of production.

As a start-up in apparel, you not only don’t benefit from economies of scale, you will most likely suffer from what I call ‘economies of stale.’ This is a term that I have made up as you probably guessed, but i’ll explain it simply below;

Economies of stale

The situation that arises when a business has to pay more that the unit price stated by the supplier because of not meeting the minimum order quantity for that item.

Although I’ve no doubt this term won’t catch on, it’s actually a really important consideration when building a start-up apparel brand. Today, I am talking about fabric sourcing, so let me run through the financial implications of sourcing when starting out, and how my newly coined term applies.

Fabric Surcharges

Europe

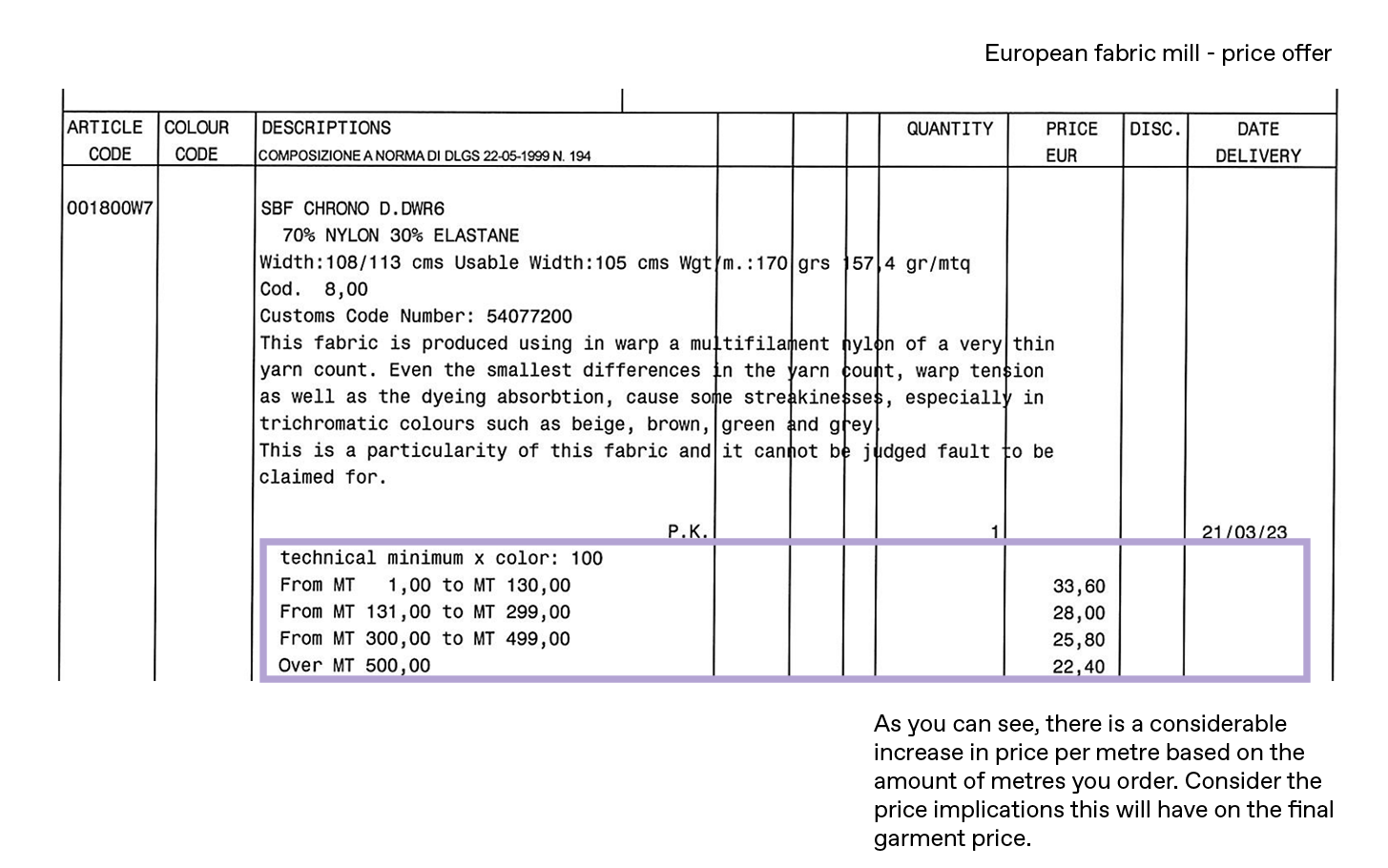

When you’re souring fabrics, there is a potential you’ll come across pricing layers. From my experience, this is more common in Europe, but simply refers to price based on the metres you order, on a sliding scale.

Looking at the example above, let’s say you’re producing 100 units of a jacket which uses 2 metres of fabric, known as consumption. Therefore, you’ll need 200 metres of that fabric to produce 100 jackets. Therefore, based on our table above, your order would all into the 131m - 299m ‘layer’ and therefor the fabric cost would look like this;

Now let’s suppose you make 250 jackets. Therefore, based on the same consumption per jacket, you need 500 metres of fabric. That will mean that you meet the highest threshold for the fabric mill and benefit from the lowest possible price, €22.40 per metre. Your breakdown would now look like this;

So, by producing 250 jackets instead of 100, from a purely material standpoint, you’d save over €11 a unit. This is a hugely significant figure in the world of manufacturing.

To put this in perspective, I have it in good authority that a billion dollar global apparel brand would 10x the price of their garment at retail based on fabric and trim cost. By that, I mean if the brand pays an extra €11 a unit in fabric cost (like our example), their retail price of that garment would increase by €110 (€11 x 10).

Although this sliding scale isn’t a surcharge in it’s traditional sense, it really highlights the difficulties start-ups face when tackling manufacturing, and the margins associated. Not only are you limited by capital to spend on marketing and acquiring customers, you’re battling with higher manufacturing costs and ultimately, a higher price per unit.

Asia

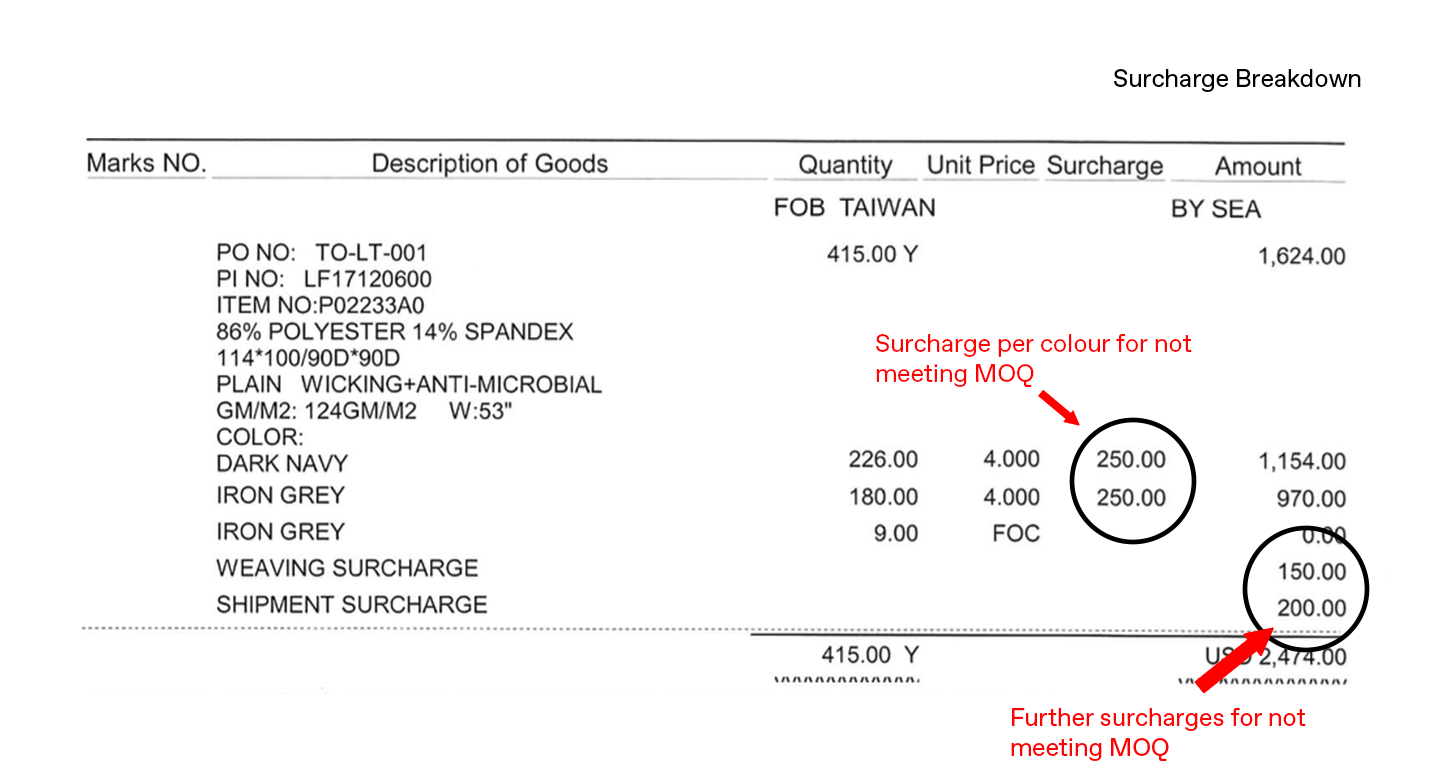

From my experience, the term surcharge is more closely associated with Asia. Surcharges, as I previously mentioned, are the added costs you as a brand have to pay due to not meeting the fabric mills or supplier MOQ’s.

In the example above, the surcharges amount to $850 on the order. Now, this order contained 415 yards of fabric, and as you can see the amount in the top right without surcharges would total $1,624 for the order, approximately $3.91 per yard. With the added surcharges of $850 split across 415 yards, the price per metre jumps to $5.96 per yard.

Although $2.00 increase may not seem significant, if we go back to the example of the windbreaker and note that you need 2 metres of fabric to produce 1 jacket, that would therefore mean the fabric alone would cost $4.00 extra per unit. If we adhere to the 10x structure that the global brand applied, that would add $40 to the retail price of the product. Significant.

In essence, the surcharges themselves are relevant against the amount of fabric you order. This is why working with Asian mills can be difficult if you’re just starting out, (on the assumption you’re manufacturing in Europe.) Let’s say you only want 200 yards, not 415 yards. The surcharges will be the same, but you now have to split the $850 surcharges over 200 yards and not 415 yards. Therefore, $3.91 (price per yard) x 200 (yards bought) = $782 (the cost of the fabric without surcharges). However, with the $850 of added surcharges, the cost would be $782 + $850 = $1,632. Therefore, to find out the price per yard, we simply divide that figure by the amount of yards bought; $1,632 / 200 = $8.16 per yard. More than double what the cost would be without surcharges.

You’re probably thinking the prices of fabric are considerably cheaper in Asia compared to a European equivalent, and you’d be right, but it doesn’t stop here. This leads us nicely onto the next consideration when sourcing from Asia, freight and duties.

Freight and duties

Whereas shipping fabric from one EU country to another allows for free trade ie. no tariffs, quotas or restrictions, the same does not apply for importing from Asia into Europe.

Understanding the different trade terms between where your manufacturer is and where your fabrics are coming from can be a critical component in fabric sourcing. There may be countries that have certain trade deals with one another that allows for free trade, or favourable trade conditions.

Freight and duties can play a significant role when you’re a small brand. If you’re importing from Asia for example, the cost of freight and duty is split across the quantity you import. However, as you import more metres of fabric, the increase in cost of importing isn’t proportional to the amount you import.

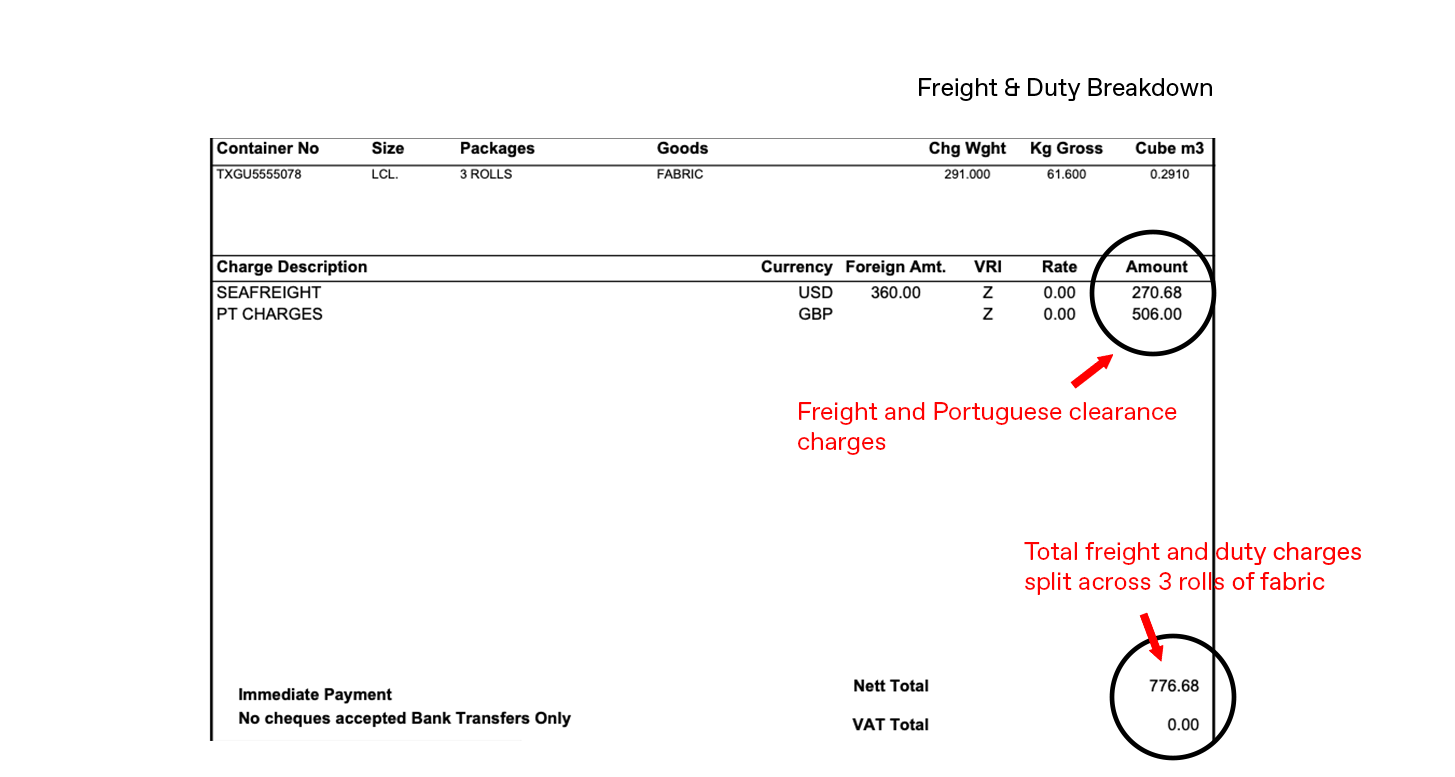

Here’s have a look at a working example from Torsa buying Merino wool a few years back;

Our Merino wool comes from New Zealand, but is ultimately dyed in Thailand, and therefore that is where the import is coming from. We ordered 3 rolls of fabric (88 yards role approximately), therefore 264 yards total. To manage the import process we enlisted a freight forwarder, who handles all of the process and a necessity for any small brand importing goods. This were the charges of freight and duties from our invoice;

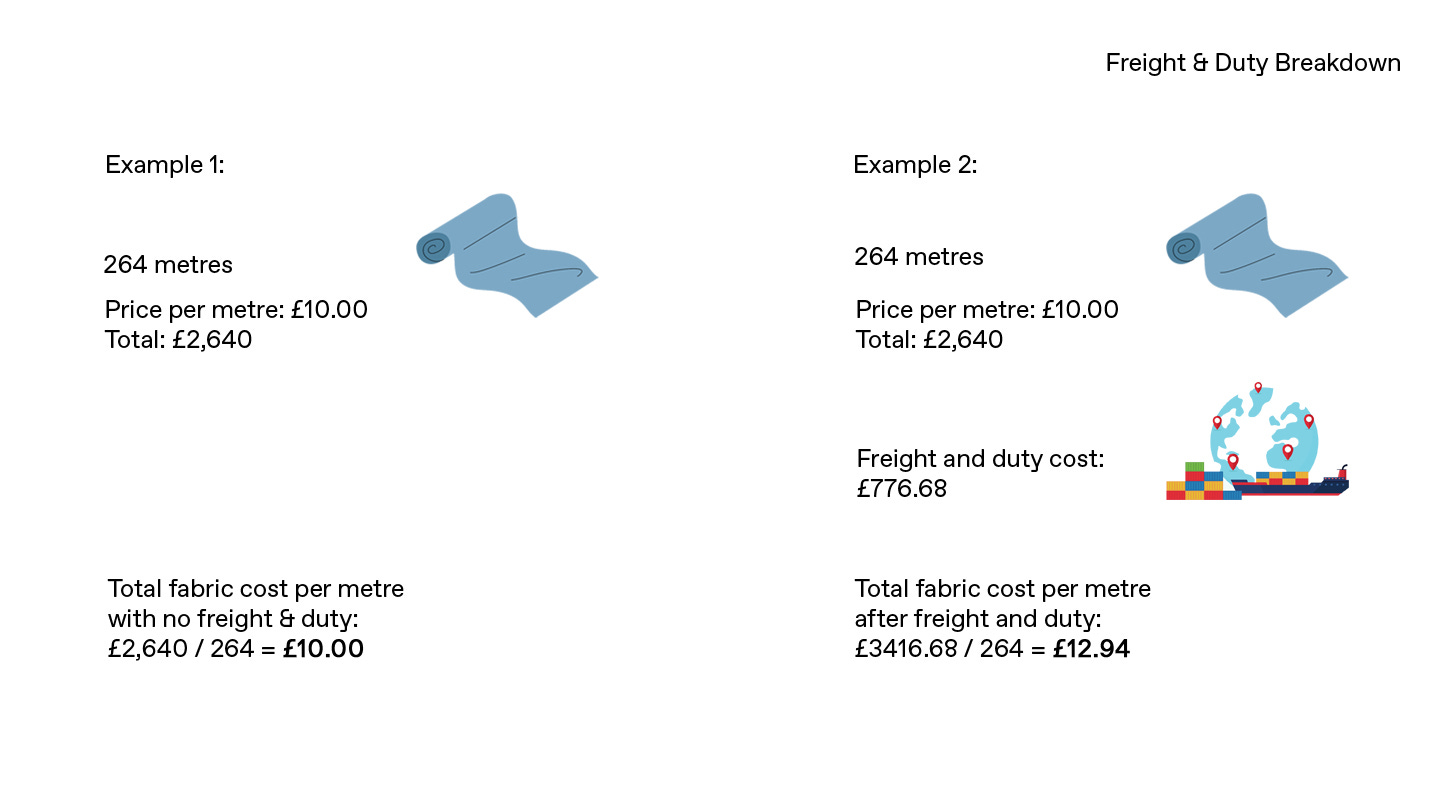

So, let’s break down the cost implication of this, and herein lies one of the issues for small brands importing from the Far East. Let’s say that the fabric cost £10.00 per yard. The total cost without freight and surcharges would be 264 (yards ordered) x £10.00 = £2,640.

So, the freight and duty adds £2.94 per yard. Of course, this is all part of developing the product. Undoubtedly, fabrics from Asia are generally cheaper than their European counterparts, however, this isn’t the end of the story.

Like I mentioned earlier, Europe offers far more generous MOQ’s. Usually, you’d be looking at 300 metres of fabric without a surcharge. This just simply isn’t the case with Asia and the Far East.

Freight, Duty and Surcharges Combined

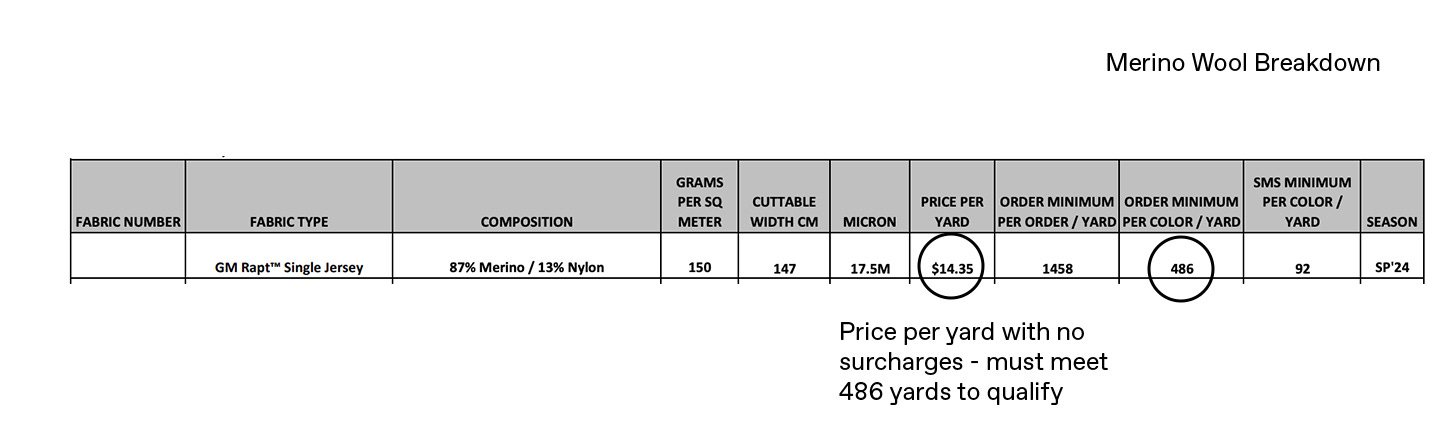

As an example, let’s go back to our Merino wool. Below is a breakdown of our Merino wool price offer from our supplier.

What’s important to note here is the price per yard and the MOQ. Remember, I am approaching this from the perspective of a start-up without significant market share or capital.

If we wanted to place an order for just one colour of this Merino wool fabric, as you can see, we have to commit to 486 yards. Therefore, assuming we order the minimum amount we’re allowed, a simple cost calculation will show that the total order for just one colour would be $6,974 (486 x $14.35).

Just think about that for a second. For the fabric alone, you’re investing nearly $7,000. Remember this is only one colour. Furthermore, this doesn’t even take into consideration the freight and duty charges, let alone the manufacture of the goods - which will almost certainly cost more than the fabric itself if producing in Europe.

So, what do you do? The two options;

Order fabric from Europe where MOQ’s are smaller, but probably more expensive

Pay the surcharges

Let’s look at the latter. We had, and did, choose to pay the surcharges that our supplier offered. It was the best Merino wool we had sourced amongst countless others, and I was committed to making it work - even though it hurt our bottom line, significantly. Surcharges will differ from supplier to supplier, but below was the charge we had to pay for not meeting the MOQ’s.

25% is brutal - there’s nothing more to say about that. At $14.35 a yard, the fabric was already very expensive. With the 25% surcharge, that jumped to $17.93 per yard. Considering that I then paid £776 to import it, the price per metre was close to $20.00 per yard, even before we started making an actual garment. You can learn more about why commercially this didn’t make sense where I discuss profit margins in a previous article;

Naivety from a commercial sense on my part, maybe, but I was committed to bringing the best Merino wool to the market, and I am proud to say that I did that.

Final Thread

This is really just touching the surface when it comes to the financial and logistics of importing fabrics. There are still a number of things to discuss (which I will do so in a future article) such as;

How buying stock colours from fabric mills can help bypass any surcharges.

‘Tagging’ onto the back of other orders in a bid to avoid surcharges.

How as you import more fabric, the freight and duties won’t rise proportionally, and therefore the more you import, the less price per metre your fabric will be.

The varying lead times of sourcing locally vs globally to your factory.

As a small brand, you have to consider your financial position and distribution strategy. Looking at our previous example of the Merino wool, there is no point importing 486 yards of the fabric (to eliminate the surcharge) to make into let’s say 480 t-shirts, if you don’t have the strategy to sell it. You’ll just end up sitting on a bunch of inventory, getting frustrated and not knowing what to do with the excess stock.

However, let’s say you have sold 280 t-shirts to wholesale ahead of the season, and then have 200 units to sell DTC. If you have an activation planned, influencer marketing strategy in place, and paid ads focus, you’re in a far better position to sell those units and benefit from the surcharge-less price. The key thing is to have a strategy in place for each scenario.